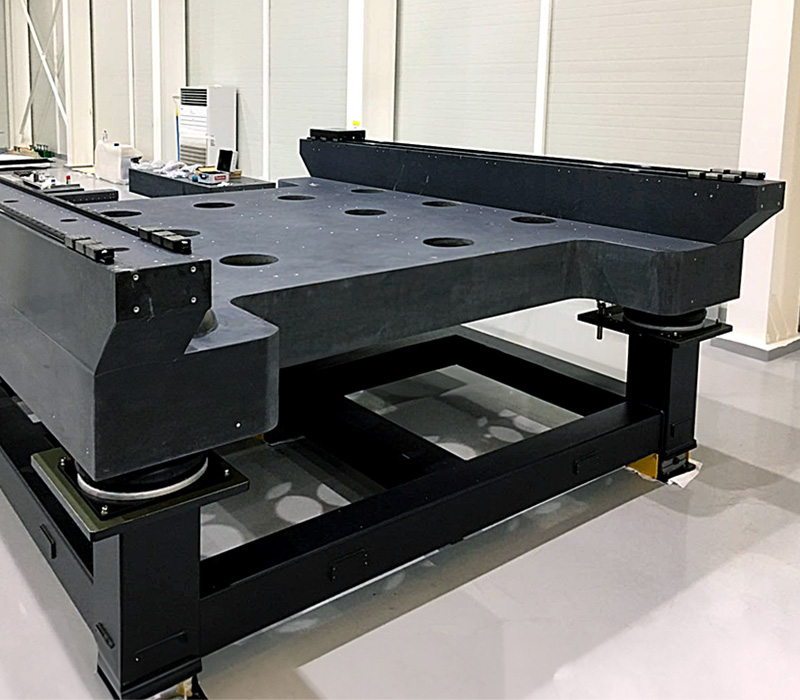

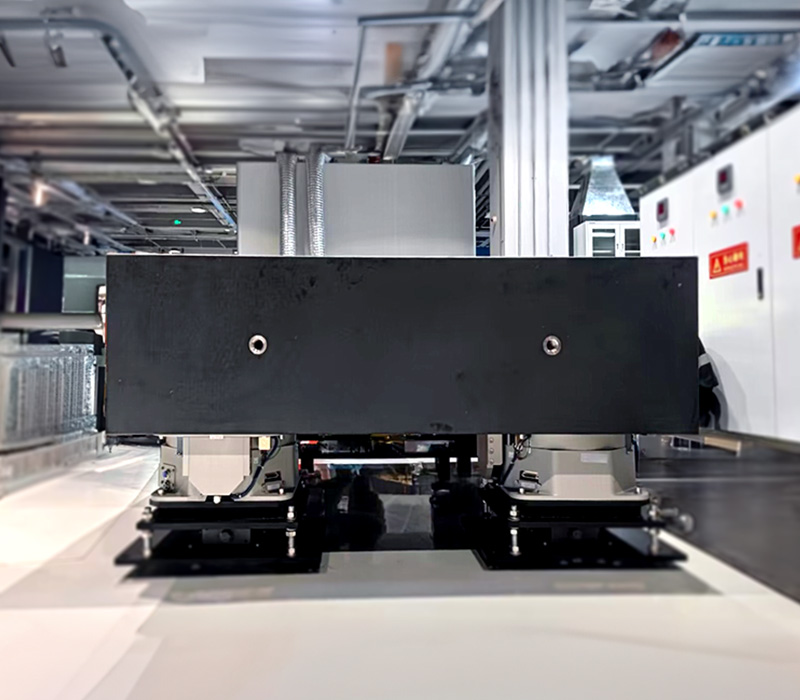

Passive vibration isolation system

Thin film air springs have precise and adjustable damping for low-frequency thin film air springs, which can be used in sensitive measurement and testing equipment, precision machining machines, laser equipment and optical electronic instruments, as well as vehicle, engine, and gearbox test benches, and have effective vibration reduction and isolation effects.

The thin film air spring isolator consists of a cast aluminum body. The air chamber is surrounded by a thin walled flexible diaphragm. Its plunger is installed on the diaphragm and pushed into the air chamber. This design has a high isolation effect. In order to achieve the highest possible damping effect, the air position is divided into two chambers. In order to suppress resonance amplification and increase damping, the internal chambers are divided into a bearing chamber and a damping chamber, which are connected by an air hose. By adjusting the valve, the damping effect can be easily adjusted from the outside. Due to the friction phenomenon caused by air flowing through the bypass valve, up to 15% of the damping will be affected. The added safety valve will protect the roller diaphragm and prevent the spring from being damaged due to excessive inflation.

▪ Efficient vibration isolation effect

▪ Sensitive measurement and detection equipment

▪ Accurate sorting machine

▪ Laser equipment and optical and electronic instruments

▪ Vibration isolation bearings for vehicle, engine, and gearbox test benches

▪ Foundation vibration isolation

Advantages compared to traditional steel springs:

The diaphragm air spring of the horizontal control device can continuously adjust the correct level of the machine and foundation, and the horizontal adjustment and control are fully automatic. The pressure in the air spring can be adjusted appropriately by inflation or deflation according to load changes. This keeps the isolation effect constant in every situation. Unlike steel springs, air springs do not transmit structural noise.

- Products

-

Solutions

- Optical Machine

- Aerospace Technology Machine

- Electronics Production Machine

- Precision Laser Processing Machine

- Semiconductor Industries

- Universities & Research Institutes

- Industrial Measurement Technologies

- Measurement & Inspection Equipment

- Precision Machining Equipment

- Vacuum Clamping Technologies

- Capability

- Blog

- About Us

- Contact